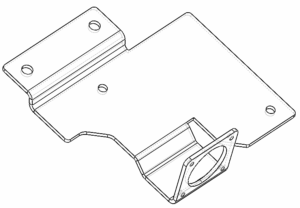

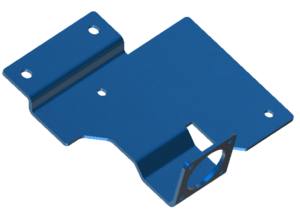

One-stop Sheet metal Services

Our one-stop sheet metal service provides complete solutions from design to delivery. We offer precision cutting, bending, and welding for various materials, ensuring high-quality custom parts. With expert guidance and efficient processes, we cater to both prototypes and large production runs, making us your reliable partner for all sheet metal needs.

On-demand Sheet metal services

Laser Cutting

Our laser cutting service utilizes state-of-the-art technology to deliver precise and intricate cuts on a variety of materials. With minimal waste and quick turnaround times, we cater to both small and large production runs, ensuring high-quality results tailored to your specifications.

Sheet Metal Bending

Our sheet metal bending service offers accurate and consistent shaping of materials to meet your design needs. With expert techniques and advanced equipment, we ensure precise angles and dimensions, providing reliable components for your projects while maintaining high-quality standards and efficiency.

Common material for Sheet metal

Here’s a table summarizing common materials used for sheet metal fabrication, along with their key properties and typical applications:

| Material | Key Properties | Typical Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Electrical components, aerospace |

| Stainless Steel | Durable, corrosion-resistant | Food processing, medical equipment |

| Carbon Steel | Strong, cost-effective | Construction, automotive |

| Galvanized Steel | Zinc-coated for corrosion resistance | Outdoor applications, roofing |

| Brass | Good machinability, corrosion-resistant | Decorative items, electrical applications |

| Copper | Excellent conductivity, corrosion-resistant | Electrical wiring, plumbing |

| Titanium | Lightweight, strong | Aerospace, medical implants |

| Nickel Alloys | Heat and corrosion resistant | High-temperature applications |

| Zinc | Protective coating for steel | Rust prevention in various applications |

| Mild Steel | Easy to work with and weld | Structural components, general fabrication |

This table provides a clear overview of each material’s characteristics and uses in sheet metal fabrication.

Start convert your ideas to physic part now!

Order parts cheaper, faster and better!

Sheet metal Size and Tolerance

If there is no 2d drawing, we will produce as per ISO-2768 V standard to machine the parts. Please check below machining size and tolerance for reference.

ISO 2768-V Tolerances

| Dimension Range (mm) | Linear Tolerance (mm) | Angular Tolerance |

|---|---|---|

| 0.5 to 3 | ±0.05 | ±0.5° |

| 3 to 6 | ±0.1 | ±0.5° |

| 6 to 30 | ±0.15 | ±0.5° |

| 30 to 120 | ±0.2 | ±0.5° |

| 120 to 400 | ±0.5 | ±0.5° |

| 400 to 1000 | ±0.7 | ±0.5° |

| >1000 | ±1.0 | ±0.5° |

Surface for CNC milled parts

We are experienced in surface treatment especially some special methods. Please check below for some common surface finish for different material parts. For special methods, please contact our technical team!

Material | Surface Finish |

Aluminum Alloy | Anodizing |

| Powder Coating |

| Plating |

| Sandblasting |

Steel | Galvanizing |

| Electro-polishing |

| Zinc Plating |

Stainless Steel | Passivation |

| Polishing |

| Bead Blasting |

Brass | Plating |

Copper | Oxidation |

| Chemical Coating |